The attached table, compares just the differences between orifice designs for two relief valves versus an initial, API design. Properly sized relief valves will provide the required protection, while also avoiding issues with excessive flow rates, including: possible valve damage, impaired performance, undersized discharge piping and effluent handling systems, and higher costs.the final, purchased, relief valve can be greatly oversized. Iv) Define set pressure, over pressure and relieving pressure of the PSV.Pressure relief valves are used to protect equipment from excessive overpressure. Many of the terms and definitions are taken fromiii) Such overpressure scenarios could be blocked outlet, control valve failure. Materi Training di DEVELOP Training Center dirancang khusus oleh para When I was young process engineer, I learnt sizing of pressure relief valve, include inlet line sizing rule: API RP 520 Part II (Ed 2003), section 4.2 recommends that the total non-recoverable pressure loss between the protected equipment and the pressure relief valve should not exceed 3 percent.Pressure Relief Valve Sizing Craig Spears November 10, 2015SIZING, SELECTION, AND INSTALLATION OF PRESSURE-RELIEVING DEVICES IN REFINERIES 5 ASME B31.1, Power Piping ASME B31.31, Process Piping ASME PTC 25, Pressure Relief Devices 3 Terms and Definitions For the purposes of this document, the following definitions apply. DEVELOP Training Center menyelenggarakan Kelas Pressure Safety Valve (PSV) Sizing&Optimization Workshop yang sangat berguna untuk mendapatkan skill tentang prinsip kerja, perancangan beserta analisa untuk optimasi Pressure Safety Valve (PSV) Sizing beserta Optimiasi PSV Valve pada Project&Plant Operation.

Psv Relief Sizing Software Features And

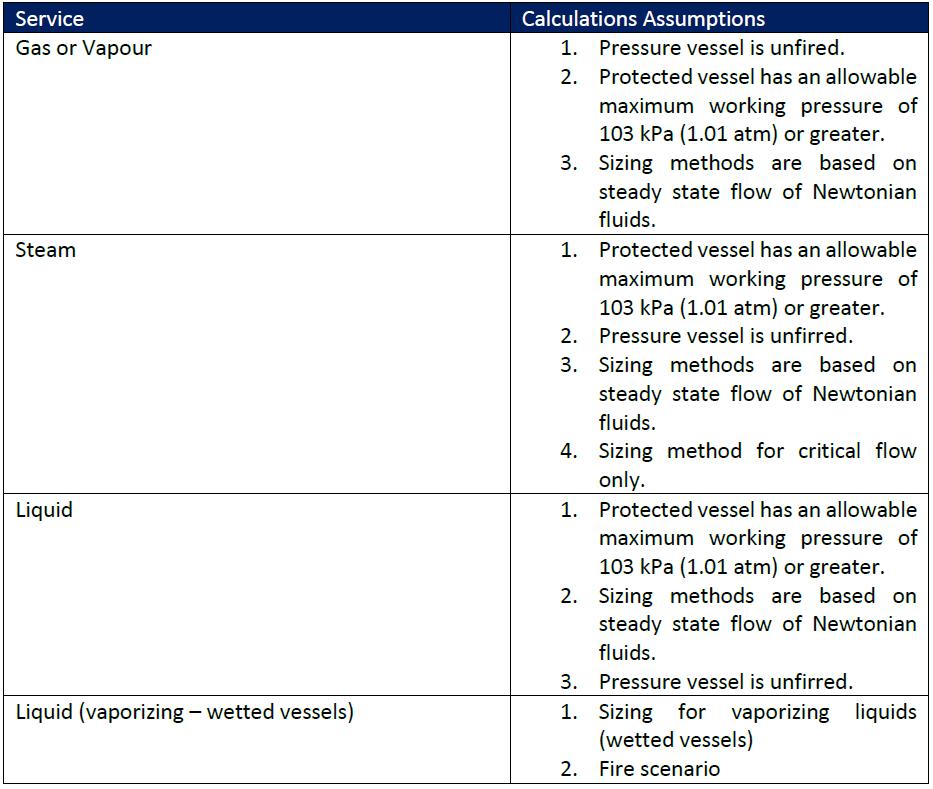

The first step in sizing a Relief Valve in ProMax is to determine which scenario you are interested in modeling.The Relief Valve Sizing in ProMax is performed as a stream analysis. Some typical cases include:In any of these scenarios, the pressure will increase until a predetermined relief pressure is reached, at which point the relief pressure valve will open, decreasing the pressure after the turnaround time. It is generally recommended to perform multiple case studies to find the most conservative sizing. This video demonstrates some software features and shows an example for sizing a valve for vapor s.Many scenarios can result in an increased vessel pressure, and each scenario may result in a different valve size.

Alternatively, the EN ISA 4126 standard accounts for thermodynamic non-equilibrium. For instance, API 520, one of the most cited standards, assumes both a mechanical and thermodynamic equilibrium, and constant phase properties during relief. Choose the Relief Valve StandardThere are many different standards for Relief Valve Sizing, each applying different assumptions, thus giving different results.

Any back pressure (downstream pressure) is additive to the spring force if this back pressure varies, then the pressure at which the valve opens will vary. When the fluid pressure exceeds the set pressure, the pressure force overcomes the spring force, and the valve opens. The operation of conventional spring-loaded pressure relief valve is based on a force balance: the spring-load is preset to apply a force opposite in amount to the pressure force exerted by the fluid on the other side when it is at the set pressure. ASME API RP520 (7th edition, January 2000) – USANext, an appropriate relief type must be selected, as sizing depends on the type of relief device selected.

Pilot Operated + Rupture Disk - Pilot Operated valve with a rupture disk. Pilot Operated - a pressure relief valve in which the major relieving device or main valve is combined with and controlled by a self-actuated auxiliary pressure relief valve (pilot). Balanced Bellows + Rupture Disk - Balanced Bellows valve with a rupture disk.

By default, ProMax uses the stream pressure as the Set Pressure, and a 10% Over Pressure, but these can be modified for your analysis.A relief device’s maximum allowable Set Pressure is equal to the vessel’s Maximum Allowable Working Pressure (MAWP) for vessels protected by a single relief device. Set the Relief PressureThe Relief Pressure is generally determined by the equipment being protected, and is calculated as Relief Pressure = Set Pressure + Overpressure. ProMax assumes that the Relief Temperature will be the current stream temperature, however, if your particular scenario requires that this be adjusted, it can be overwritten directly in the analysis dialog.

For spring-operated relief valves, a small amount of leakage occurs at 92-95% of the Set Pressure, and sufficient Over Pressure is necessary to achieve full lift. The Back Pressure includes both the constant superimposed downstream pressure and any built-up backpressure due to the discharge of the fluid from the relief device through the downstream piping and treatment system.The Over Pressure is usually expressed as a percentage of the Set Pressure. In cases where the MAWP is not well-established, the design pressure may be used for the set pressure.The Set Pressure is usually given in terms of gauge pressure, therefore any Back Pressure is added to the set pressure and overpressure to calculate the Relief Pressure in absolute units. In some cases, the design pressure is equal to the MAWP – but it will never exceed it. As the MAWT increases, the MAWP decreases because of the reduction in strength of metal at higher temperatures.However, relief devices are typically set to open at the design pressure, instead.

When multiple relief devices are used for non-fire scenarios, the allowable accumulation is 116%. The allowable accumulation for pressure vessels protected by a single relief device is 110% of the MAWP, except in fire exposure scenarios where 121% is allowed. In cases where the Set Pressure is equal to the MAWP, then the overpressure and pressure accumulation are the same.

Due to the large number of variables associated with the fluid properties,Distribution of fluid phases, interaction, and transformation of the phases, sizing a two-phase relief scenario is considerably more complex than single-phase. Real valves are not ideal nozzles, so a discharge coefficient, K D, isUsed to account for the difference between the predicted ideal nozzle and the actual mass flux in the valve.The discharge coefficient, K D, can be estimated by ProMax or specified directly from vendor literature.Single and two-phase flows are both frequently encountered in various relief scenarios. The rate of increase in velocity is greater than the rate of decrease in density, therefore the mass flux reaches a maximum at the throat.Determined for the particular emergency scenario, the minimum required area ( A min) is calculated at the maximum mass flux,Which was determined to occur at the nozzle throat.

However, flashingIs usually not instant and during this period liquid can travel several inches in the nozzle of the valve under typical relief conditions. When the pressure drops to the saturation pressure of the liquid, flashing occurs instantly if thermodynamic equilibrium is assumed. Although there are a variety of models in the literature for estimating the slip as aFunction of fluid properties and flow conditions, it is often neglected under pressure-relief conditions because of the high degree of turbulence and mixing.It is commonly assumed that the gas or vapor phase is in local thermodynamic equilibrium with the liquid phase, meaning the properties of the mixture are a function of only the localTemperature, pressure, and composition.

0 kommentar(er)

0 kommentar(er)